Before realising this project, you must read the previous 10$ air laser simple project: no special gas, no chemical products, no vacuum and no glass work!

The 10$ air laser use L aluminium rules electrodes in a symmetrical way: |_ _| plasma is created between electrodes.

This is a very simple way but, due to the "open structure", laser uses air at normal pressure only. This laser is also noisy: spark gap is noisy and laser channel also: when electrical discharge occurs, a very high current (few 1000 A) flows for some ns (nanoseconds): the air temperature increase very fast: at each pulse, air very fast dilatation make a little "bang"

How to decrease noise, use air at a non atmospheric pressure or another gas like Nitrogen and be able to adjust electrodes distance and parallelism?

Of course, we can use nice clear Plexiglass cylinders and many other pretty solutions... but it's a lot of work and low leakage is difficult. Here is a solution based on my experiment. I still want a modular solution: something easy to disassemble to exchange any parts. We glue only flat large surface to easily be completely proof.

Once more, we mustn't forget the inductor problem: parasitic inductor must be at an absolute minimum. The loop area from capacitor plate to plasma channel must be minimum.

My solution is based on 2 U aluminium rules glued with PCB (Printed Circuit Board without copper) plates to make a box:

[ ]

Inside this box are installed 2 L aluminium rules |_ _| with 2 horizontal push springs and 2 another vertical push spring, one per electrode.

The bottom is closed with a rectangular PCB plate glued with epoxy. The top is covered with a clear plastic plate glued with silicon to be easily removed. On each end, a 10 x 10 mm hole is made, a 18 x 18 mm microscope glass slide is glued with silicon for laser output. Then the box is entirely closed.

How can we adjust electrodes distance and parallelism ? We use some special medical plastic or rubber bellows like an accordion. This allows user to adjust distance without leakage. It can be adjusted even while lasing !

Caution: due to vacuum, rubber bellows diameter must be little enough and push springs must be strong enough to prevent outside atmospheric pressure to push bellows and electrode inside ! (That's not the case on this prototype ;-)

Picture shows elements for this structure (CD-ROM is just for scale): from left to right: bottom PCB plate, U rules box glued to PCB plates, L electrodes and 2 horizontal and 2 vertical push springs, clear plastic top. (Microscope slides are missing)

Pictures show the top structure without the bellows accessories, microscope slides, PCB bottom and clear plastic top:

We can see horizontal push springs (which act also as inductor) and 1 vertical push spring (this one pushes the non adjustable L electrode)

And the bottom: we see the 2 electrodes which distance is here set to about 1.5 mm (atmospheric pressure)

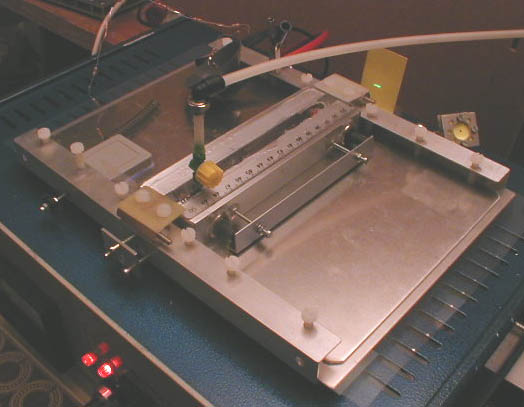

Then this structure is put and attached on the 10$ air laser structure with capacitors, spark gap and XY adjustable rear mirror.

We then make preliminary high-tension tests with open air at atmospheric pressure (before gluing top bottom and slides)

A faucet is glued in a hole made on the clear plastic top, some accessories are added to help electrodes adjustment. A pressure meter and a fridge pump are added and it's ready for low pressure or non-air gas test.

Here, the sealed structure is finished, glued with epoxy and silicon, rubber accessories and a L aluminium rule and screws to adjust distance are installed, microscope slides are glued, clear plastic cover with a faucet. All that is put on the laser capacitors

Bottom picture: bottom side is closed with a piece of epoxy PCB (printed board) epoxy glued. We can see a push spring through the output closed wit a microscope slide silicon glued.

Sealed structure is installed in the laser. Even with air, using low-pressure make laser easier to lase and with stronger output with a lot of pressure/distance combinations.

They are still mysterious things in these lasers: this laser use same capacitors and about same electrodes (a little bit shorter) as previous 10$ air laser, at atmospheric pressure, completely open, without glass windows and clear plastic top, this laser has less output than the 10$ air laser. Why ???

http://spt06.chez-alice.fr/00/lasers.htm

Any comments?

E-mail :

03/06/05.